Product Consultation

Your email address will not be published. Required fields are marked *

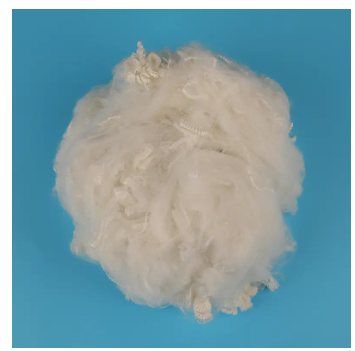

In the spectrum of synthetic fibers, polyester staple fiber (PSF) has become a bridge between traditional textiles and high-end manufacturing due to its unique molecular structure and process plasticity. This short fiber made from polyethylene terephthalate (PET) by melt spinning and cutting is reshaping the underlying logic of modern industry through breakthroughs in material science and collaborative innovation in the industry.

The molecular chain of PSF is composed of a rigid benzene ring structure and a flexible methylene chain segment. This "rigid-flexible coupling" chemical feature gives it three core advantages:

Thermomechanical stability: Maintaining mechanical properties in a wide temperature range of -100℃ to 175℃, long-term use temperature up to 160℃, short-term tolerance to high temperature of 190℃, and achieving a 10,000-hour creep strain stability of <1% in electronic and electrical insulation parts

Precise dimensional control: Molding shrinkage is <0.5%, and the dimensional accuracy of 0.1% can still be maintained in a hot and humid environment, meeting the stringent requirements of precision instruments for material stability

Chemical tolerance threshold: In addition to concentrated sulfuric acid and nitric acid, it can resist erosion by acid and alkali salt solutions, and only reversible swelling occurs in ketone solvents, making it an ideal substrate in the field of chemical filtration

This molecular-level characteristic enables it to show performance potential that exceeds natural fibers in scenarios such as medical implants and seawater desalination membranes. For example, the PSF reverse osmosis membrane prepared by sulfonation modification technology has a 30% increase in flux compared with traditional materials while maintaining a 98% salt rejection rate, indicating the material's ability to precisely control the microscopic scale.

The manufacturing process of PSF has formed three major technical routes: direct spinning, slice spinning, and recycled spinning, building a technical matrix covering the entire industry chain:

Direct spinning process: Through the continuous polymerization of PTA and MEG, direct spinning reduces energy consumption by 15% compared with traditional processes. Its product, virgin staple fiber, occupies 47% of the market share, forming a scale effect in the field of spinning and filling materials

Slice spinning technology: Using fiber-grade PET slices as raw materials, rapid product switching and flexible production are achieved, so that the proportion of differentiated products such as cationic, colored, and ultra-fine denier exceeds 30%, meeting the demand for fiber functionality of high-end clothing

Recycled spinning system: By recycling PET bottle flakes and then melting and spinning, a closed loop of circular economy is constructed. After GRS certification, its products have formed differentiated competitive advantages in the environmentally friendly home textile and outdoor equipment markets

Process innovation is driving PSF to evolve towards functionalization and intelligence. For example, through nanoparticle doping technology, conductive fibers with conductivity exceeding 10⁻³ S/cm can be prepared, showing application potential in the fields of static elimination and flexible sensing; and surface plasma treatment technology enables the pore size control accuracy of PSF membranes to reach 0.2μm level, promoting the biocompatibility of hemodialysis membranes by 60%.

The market structure of PSF is undergoing structural changes, and its application boundaries have broken through the traditional textile field. From clothing fabrics to aerospace structural parts, from sewage treatment to intelligent sensing, the evolution of PSF is a microcosm of the development of modern materials science. This seemingly ordinary synthetic fiber is interpreting the industrial logic of "small fibers leveraging big industries" through molecular design, process innovation, and interdisciplinary integration. When materials science enters the era of precise control, every performance leap of PSF may trigger a disruptive change in a certain industry-this may be the most fascinating evolutionary code of industrial civilization.

Recycle Wool Spinning Fiber Series: A Sustainable Textile Revolution

2025-04-22

Recycle Non-Woven Fibers Series: Opening a new era of sustainable materials

2025-05-08Your email address will not be published. Required fields are marked *

Focusing to the research and production of differentiated fiber. Applying recycle-material processing scientifically.

Zhulinjizhen, Xinfeng Town, Jiaxing City, Zhejiang Province

Copyright @ 2023 Jiaxing Fuda Chemical Fiber Factory All rights reserved

Polyester Staple Fiber Manufacturers

Friendship link - Anhui Fulin Environmental Protection Technology Co., Ltd.:https://www.ahflhb.com