Product Consultation

Your email address will not be published. Required fields are marked *

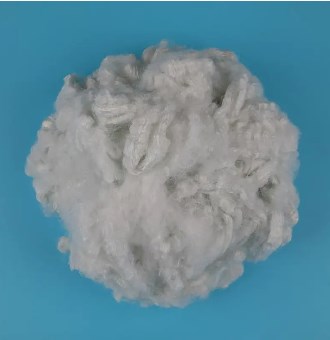

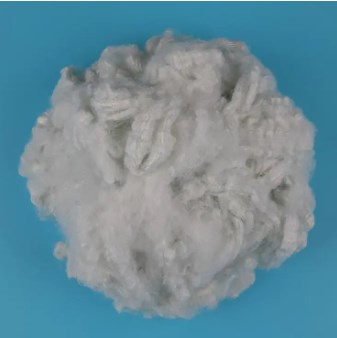

Amidst the rapidly evolving textile technology landscape, one material, with its unique structure and exceptional performance, is quietly leading a profound transformation. It's hollow conjugated fibers. This somewhat unfamiliar term holds immense technological potential. It's more than just a simple upgrade of traditional fiber materials; it represents a game-changing innovation, opening up a whole new path for comfort, functionality, and sustainability in textiles.

The Beauty of Structure: A Perfect Interweaving of Hollowness and Conjugation

To understand the uniqueness of hollow conjugated fibers, we must first examine their microstructure. As the name suggests, these fibers cleverly combine two core characteristics: hollowness and conjugation.

First, the "hollowness." Unlike traditional solid fibers, hollow conjugated fibers exhibit a hollow, tubular structure in cross-section. This hollow structure isn't simply a hollow cavity; it's meticulously designed and precisely controlled. This significantly reduces the fiber's overall weight, making fabrics made from it even lighter. More importantly, the hollow core creates a stable air layer, acting as a natural thermal barrier. Air has an extremely low thermal conductivity, so the hollow structure effectively blocks heat transfer, giving the fiber excellent thermal insulation. Imagine a down jacket of the same thickness: its warmth comes largely from the air trapped by the fluffy down. Hollow fibers achieve a similar thermal insulation mechanism through this inherent structure.

Secondly, conjugation is the core of hollow conjugated fiber technology and what distinguishes it from conventional hollow fibers. Conjugation spinning technology involves the conjugation of two or more polymers with different properties into a single fiber through a specialized spinneret structure. In hollow conjugated fibers, two polymers with different shrinkage rates are typically used. When the fiber is heat-treated, the differential shrinkage between the two polymers causes it to spontaneously deform into curls, spirals, or waves. This unique three-dimensional curling structure imparts excellent bulk and elasticity. This curl is not simply a bend; it forms a long-lasting, three-dimensional structure with memory, allowing it to quickly return to its original bulk even after repeated stretching and compression. It is this conjugated crimp that creates more spaces between the fibers, further enhancing thermal insulation while also providing exceptional softness and a comfortable feel.

Thus, the microstructure of hollow conjugated fibers can be vividly described as a tube with a hollow interior and three-dimensional crimps on the exterior. This dual structure works synergistically to create its exceptional performance.

A Leap in Performance: A Multi-Dimensional Upgrade from Comfort to Function

The unique structure of hollow conjugated fibers surpasses traditional fibers in many aspects, achieving a leap in performance.

Excellent thermal insulation and a lightweight feel are its most significant advantages. As mentioned above, the air layer within the hollow structure and the fluffy structure created by the conjugated crimps combine to create a powerful thermal insulation system. This allows thermal insulation materials made from them to be lighter while maintaining the same warmth. This makes them highly attractive for applications such as outdoor sportswear, winter underwear, and bedding. Consumers no longer have to choose between warmth and lightness.

Excellent loft and resilience are another key feature. The conjugate crimp imparts the fiber with long-lasting elastic recovery, making the resulting filling less prone to clumping and collapse. Whether used as filling for clothing, pillows, or quilts, it maintains its fullness and loft for extended periods, providing continuous, comfortable support. This performance significantly extends the product's lifespan, reduces replacement frequency, and aligns with sustainable development.

Hollow conjugate fibers also exhibit excellent moisture-wicking properties. The hollow structure not only traps air but also facilitates the rapid diffusion of moisture. Compared to some solid synthetic fibers with poor hygroscopicity, hollow conjugate fibers effectively manage body moisture while retaining warmth, keeping the wearer dry and comfortable. This makes them a significant advantage in applications such as sportswear and outdoor gear that require both warmth and breathability.

Wide Applications: Reshaping the Future of Textiles

The excellent properties of hollow conjugate fibers offer broad application prospects in a wide range of fields, gradually reshaping the future of textiles.

In clothing, they have become an ideal choice for high-performance thermal insulation. From lightweight, warm jackets to comfortable, form-fitting winter underwear to specialized ski and mountaineering apparel, hollow conjugate fibers offer lightweight, highly thermal, and breathable solutions. They empower outdoor enthusiasts to explore more freely and allow everyday wearers to enjoy unfettered activities even in cold weather.

In the home furnishing sector, hollow conjugate fibers are gradually replacing traditional down and conventional synthetic fibers. Quilts, pillows, and mattresses made from them not only offer a soft, fluffy feel, but also offer excellent warmth and resilience, providing consumers with a superior sleep experience. Their anti-allergenic properties also make them a suitable alternative for those with allergies.

Beyond traditional textiles, hollow conjugate fibers are finding new applications in technical textiles. For example, their unique structure improves filtration efficiency in filter materials. In nonwovens, their high volume and elasticity make them ideal for sound absorption and shock absorption. Their lightweight, warm, and functional properties are also being explored and applied in automotive interiors and medical supplies.

Hollow conjugate fibers are more than just a new material; they represent a fundamentally new design concept and technological paradigm. Through sophisticated microstructural design, they achieve significant improvements in macroscopic performance, striking a perfect balance between comfort, functionality, and sustainability. With continued advancements in spinning technology and innovations in polymer materials, hollow conjugate fibers will play an increasingly important role in the future textile world, continuously bringing us lighter, warmer, and more comfortable wear experiences.

Unlocking a New Dimension in Materials Science: The Breakthrough Applications and Future Potential of Hollow Microfibers

2025-08-08

Recycle Non-Woven Fibers Series: A Fusion of Environmental Protection and Innovation

2025-08-22Your email address will not be published. Required fields are marked *

Focusing to the research and production of differentiated fiber. Applying recycle-material processing scientifically.

Zhulinjizhen, Xinfeng Town, Jiaxing City, Zhejiang Province

Copyright @ 2023 Jiaxing Fuda Chemical Fiber Factory All rights reserved

Polyester Staple Fiber Manufacturers

Friendship link - Anhui Fulin Environmental Protection Technology Co., Ltd.:https://www.ahflhb.com