Product Consultation

Your email address will not be published. Required fields are marked *

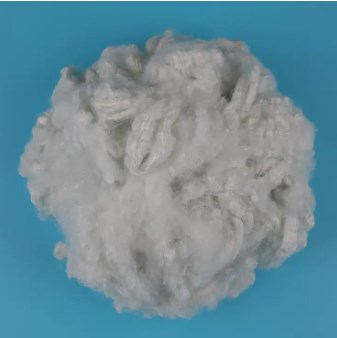

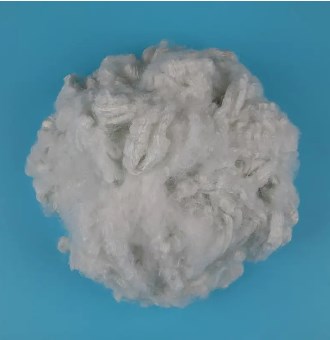

In the microscopic world of materials science, hollow microfibers, with their unique structure and properties, are becoming a key player in cross-disciplinary innovation. These fibrous materials, typically measuring micrometers in diameter, are named for the continuous cavity at their center and demonstrate exceptional value in the textile industry. Their design draws inspiration from the hollow structure of plant stems in nature—those seemingly slender stems are able to support the weight of the entire plant while efficiently transporting water and nutrients through their hollow channels—and also incorporates the precise control techniques of modern materials engineering. Compared to traditional solid fibers, hollow microfibers offer significant advantages in quality, breathability, and warmth. They are gradually reshaping the technological landscape in areas such as apparel, home textiles, and industrial textiles, injecting new vitality into the entire textile industry.

Structure and Materials: The Secret to Textile Performance of Hollow Microfibers

The core competitiveness of hollow microfibers lies in their sophisticated structural design and diverse material options, which make them irreplaceable in the textile industry. Structurally, the presence of hollow cavities not only significantly reduces material density, making textiles lighter and weightless when worn or used, but also creates unique air storage spaces. These cavities act like miniature thermal chambers, effectively blocking heat transfer and enhancing the textile's thermal insulation properties. Furthermore, the presence of these cavities alters the stress distribution within the fibers, enhancing their loftiness and allowing the fabric to quickly recover after compression, resulting in greater elasticity and resilience, and resisting deformation even after prolonged use.

The choice of material determines the functional boundaries of hollow microfiber textiles. Currently, mainstream materials used in hollow microfibers include polymers such as polyester, polyamide, and polypropylene. Polyester-based hollow microfibers, due to their excellent abrasion resistance and shape retention, are widely used in outdoor clothing and sportswear. Whether on rugged mountain hikes or during intense ball games, garments made from hollow microfibers can withstand frequent friction and stretching, maintaining a crisp shape. Polyamide-based products, with their excellent moisture absorption and soft feel, are ideal for intimate apparel. They quickly absorb sweat from the skin's surface and dissipate it through the fiber structure, keeping the skin comfortable.

Polypropylene-based hollow microfibers, on the other hand, are commonly used in home textiles due to their low cost and chemical resistance. They maintain stable performance even when exposed to chemicals such as detergents during daily cleaning. By adjusting the material composition and preparation process, researchers can also impart special features such as antibacterial, antifouling, and antistatic properties to hollow microfiber textiles, adapting them to more complex applications. For example, in medical textiles, antibacterial properties can effectively reduce bacterial growth and protect the user's health.

Cross-border Applications: Expanding Diverse Applications in the Textile Industry

Hollow microfibers are particularly effective in the clothing sector. Their lightweight nature eliminates the need for heavy winter clothing, ensuring warmth while allowing the wearer greater freedom of movement. Traditional winter clothing, to achieve warmth, often uses heavy fabrics and fillings, which not only makes the wearer bulky but also restricts movement. Winter clothing made from hollow microfibers, thanks to their unique hollow structure, traps air, creating an effective insulation layer. This reduces weight without sacrificing warmth.

For example, down jackets made with hollow microfibers are not only lighter than traditional down but also less likely to clump. Traditional down tends to clump after repeated use or washing, affecting its warmth and comfort. However, hollow microfiber fillings maintain their loft and warmth over time, keeping down jackets light and comfortable. Furthermore, hollow microfiber fabrics offer excellent breathability. The gaps between the fibers and the hollow structure create smooth airflow channels, effectively dissipating moisture from the body, keeping the skin dry and significantly improving comfort. Even after strenuous exercise, the feeling of heat and humidity is eliminated.

The home textile industry is another important area where hollow microfibers demonstrate their unique value. Bedding made from them, such as duvet covers and pillowcases, is soft and smooth to the touch, and extremely skin-friendly. When these home textiles come into contact with the skin, they feel neither rough nor itchy, providing an exceptionally comfortable experience. The hollow structure creates a fluffier feel, making the bedding lighter and more contoured to the body. Traditional bedding is often thick and heavy, making it difficult to conform to the body as you move during sleep, impacting sleep quality. Hollow microfiber bedding, on the other hand, adapts to the body's shape, providing just the right amount of support and support, enhancing sleep quality.

Hollow microfiber home textiles also offer excellent washability, maintaining their original shape and performance after repeated washes. Traditional home textile materials are prone to shrinkage, deformation, and pilling after repeated washes, while hollow microfiber materials are highly stable. Whether machine or hand washed, they maintain their original size and appearance, extending their lifespan far beyond that of traditional home textiles.

Hollow microfibers are also increasingly being used in the industrial textile sector. In filtration textiles, the hollow structure and inter-fiber spaces of hollow microfibers form a multi-layered filter barrier, effectively trapping airborne particles and impurities in liquids while ensuring excellent breathability. This plays a vital role in industrial waste gas treatment and water purification. In agricultural textiles, covering materials made from hollow microfibers effectively regulate temperature and humidity, creating a suitable environment for crop growth. Their durability also allows them to withstand the complex climatic conditions of the field.

In the future, the development of hollow microfiber textiles will place greater emphasis on multifunctional integration and intelligent technology. Special surface treatments can be applied to fibers to enable them to respond to environmental changes, such as temperature-sensitive color changes and humidity regulation, enabling dynamic control of textile functionality. For example, in summer clothing, specially treated hollow microfibers can alter their structure when the external temperature rises, increasing breathability and helping dissipate heat. When the temperature drops, they decrease breathability to maintain body temperature. In the field of smart wearables, the combination of hollow microfibers and electronic components could lead to the development of clothing with health monitoring capabilities. These devices could monitor physiological indicators such as heart rate, temperature, and blood pressure in real time, and transmit this data to relevant devices, facilitating health management.

The development of hollow microfibers in textiles vividly demonstrates the deep integration of materials science and textile technology. With continued technological advancement, these microscopic structural innovations will continue to bring transformative breakthroughs to the textile industry, bringing more comfortable, intelligent, and environmentally friendly textile products to people's lives, and driving the entire textile industry towards higher quality and more sustainable development.

Composite ES Fiber: Innovation and Breakthrough for the Future Textile Industry

2025-08-01

Hollow Conjugated Fibers: A Disruptive Revolution in the Next Generation of Textile Materials

2025-08-15Your email address will not be published. Required fields are marked *

Focusing to the research and production of differentiated fiber. Applying recycle-material processing scientifically.

Zhulinjizhen, Xinfeng Town, Jiaxing City, Zhejiang Province

Copyright @ 2023 Jiaxing Fuda Chemical Fiber Factory All rights reserved

Polyester Staple Fiber Manufacturers

Friendship link - Anhui Fulin Environmental Protection Technology Co., Ltd.:https://www.ahflhb.com