Product Consultation

Your email address will not be published. Required fields are marked *

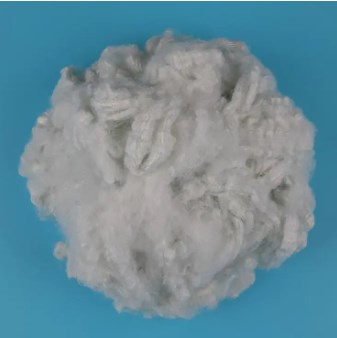

With the continuous advancement of technology and the diversification of industrial needs, the research and development and application of textile materials have become increasingly important. As a new type of high-performance fiber, composite ES fiber, with its excellent properties, is gradually becoming a key raw material in the textile industry.

Definition and Characteristics of Composite ES Fiber

Composite ES fiber is a high-tech fiber composed of multiple fiber materials. Common composite forms include polyester and polyamide blends or a combination of multiple functional fibers. ES fiber itself possesses unique properties and is widely used in applications such as high strength, high-temperature resistance, waterproofing, fireproofing, and UV resistance. The emergence of composite ES fiber further enhances its functionality and improves its adaptability to extreme environments.

The primary characteristics of composite ES fiber are its high strength and toughness. Compared to traditional single fibers, composite ES fiber has significantly improved tensile strength and abrasion resistance. Composite ES fiber also exhibits excellent high-temperature resistance, maintaining stable physical and chemical properties even in high-temperature environments, which has led to its widespread application in industrial and military fields.

Applications of Composite ES Fiber

Composite ES fiber has a wide range of applications, spanning high-performance textiles to industrial materials. In the textile industry, composite ES fiber is used to produce high-performance apparel, particularly protective clothing, sportswear, and outdoor apparel, achieving new heights in tensile strength, comfort, and durability. Composite ES fiber's strong waterproof and breathable properties make it an ideal material for outdoor equipment, raincoats, and other products.

In the industrial sector, composite ES fiber, due to its high-temperature and corrosion resistance, is widely used in protective equipment for high-temperature environments. For example, in industries like metallurgy and chemicals, composite ES fiber is often used to make high-temperature protective clothing and thermal insulation materials, effectively protecting people and equipment from high-temperature damage.

Composite ES fiber also has important applications in industries such as aerospace, automotive, and military. In these fields, fiber strength, high-temperature resistance, and UV resistance are crucial. Composite ES fiber meets these stringent requirements, helping to create safer and more durable products.

Environmental Benefits of Composite ES Fiber

With growing global awareness of environmental protection, the environmental pollution caused by the production and processing of traditional fibers is gaining increasing attention. As an environmentally friendly material, composite ES fiber offers unique advantages in sustainable development. The raw materials used in the production of composite ES fiber can be partially derived from renewable resources, reducing reliance on traditional petrochemical resources. Composite ES fiber itself is highly recyclable after use, effectively reducing the environmental burden of waste.

Composite ES fiber also has low energy and resource consumption. Due to its high strength and durability, products made with composite ES fiber tend to have a longer service life, thereby reducing the reuse of resources and the generation of waste. During the production of composite ES fiber, process technology is continuously optimized, reducing harmful gas emissions and further promoting green development in the textile industry.

Market Prospects of Composite ES Fiber

As consumers demand higher performance in textiles, market demand for composite ES fiber is steadily growing. In particular, composite ES fiber, due to its unique advantages, is gaining wider application in high-end markets and specialized fields such as military, aviation, and medical. These fields place extremely stringent demands on textiles, and the powerful functionality of composite ES fiber precisely meets these needs.

Future Development Direction: Intelligence and Multifunctionality

With the continuous advancement of technology, the future development of composite ES fibers will show a trend towards intelligence and multifunctionality. Future composite ES fibers will not only be limited to improving physical properties but may also incorporate emerging technologies such as nanotechnology and smart sensors to achieve intelligent sensing and real-time monitoring. This will enable composite ES fibers to not only gain a foothold in traditional fields but also open up new markets.

The Versatile World of Polyester Staple Fiber: From Apparel to Industry

2025-07-22

Unlocking a New Dimension in Materials Science: The Breakthrough Applications and Future Potential of Hollow Microfibers

2025-08-08Your email address will not be published. Required fields are marked *

Focusing to the research and production of differentiated fiber. Applying recycle-material processing scientifically.

Zhulinjizhen, Xinfeng Town, Jiaxing City, Zhejiang Province

Copyright @ 2023 Jiaxing Fuda Chemical Fiber Factory All rights reserved

Polyester Staple Fiber Manufacturers

Friendship link - Anhui Fulin Environmental Protection Technology Co., Ltd.:https://www.ahflhb.com