Product Consultation

Your email address will not be published. Required fields are marked *

Polyester Staple Fiber has become an indispensable material in the global textile industry chain. As a form of polyester fiber, it plays a key role in clothing, home textiles, technical fabrics, and other fields with its stable performance, wide application, and excellent cost-effectiveness. With the continuous upgrading of the textile industry, this fiber is not only a basic raw material but also a core driving force for textile product innovation and sustainable development.

Definition and Characteristics of Polyester Staple Fiber

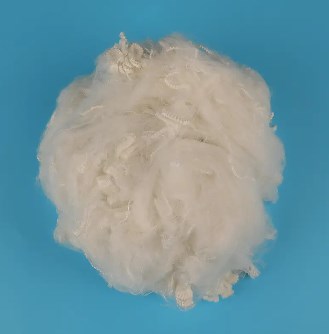

Polyester Staple Fiber is a short fiber made from polyester chips through melt spinning, cooling, drawing, and crimping. Compared to filament, it is closer to the structure of natural fibers, has a softer feel, and is easily blended with natural or chemical fibers such as cotton, wool, and viscose. The fiber length is generally tens of millimeters, making it highly processable in spinning and weaving.

Its greatest advantages are high strength, good elasticity, and abrasion resistance. It also has low moisture absorption and strong wrinkle resistance, maintaining a smooth appearance. After undergoing a crimping process, polyester staple fiber creates excellent cohesion during the spinning process, resulting in a uniform and fine yarn. It also exhibits excellent light and heat resistance, and can withstand repeated washing without deformation.

Application Value of Polyester Staple Fiber in Textiles

In apparel fabrics, polyester staple fiber is widely used in knitted and woven products. It not only enhances the fabric's stiffness and durability, but can also be blended with natural fibers to improve hand feel and breathability. For example, in the cotton textile industry, cotton yarn blended with polyester staple fiber combines the softness and comfort of cotton with the abrasion resistance and deformation resistance of polyester, resulting in a product that is both comfortable and durable.

In the home textile industry, it is widely used in bedding, sofa fabrics, curtains, and carpets. These products require high durability and color fastness, and polyester staple fiber helps maintain color vividness and prolong the product's lifespan. In carpet production, polyester staple fiber is particularly favored for its stain resistance and easy-to-clean properties.

Polyester staple fiber also holds significant value in the industrial fabrics sector. It has important applications in nonwovens, filter materials, medical materials, and automotive interiors. These materials require excellent strength and stability, and polyester staple fiber precisely meets these requirements. For example, in nonwovens production, it can be combined with polypropylene fiber to improve the product's tensile properties and service life.

Polyester Staple Fiber Production Process and Technological Development

The manufacturing process for polyester staple fiber includes melt spinning, cooling, drawing, and cutting. During this process, polyester chips are melted at high temperatures and extruded into filaments. They are then cooled and shaped, then drawn to enhance the molecular chain alignment and fiber strength, before being cut into staple fibers. Some products are crimped to impart natural-fiber-like bulk and cohesion, making them more suitable for spinning.

With the advancement of textile technology, the production process for polyester staple fiber is continuously optimized. Differentiated functional staple fibers, such as hollow fibers, flame-retardant fibers, and antimicrobial fibers, are becoming a new market trend. These functional products bring higher added value to textiles and expand the application areas of polyester staple fiber. For example, hollow fibers, due to their lightweight and thermal properties, are widely used as filling materials, while antimicrobial staple fibers play an important role in medical protective fabrics.

Polyester Staple Fiber and Sustainable Development

Amid the global textile industry's green transformation, polyester staple fiber is also actively developing towards environmentally friendly approaches. Recycled polyester staple fiber has emerged as a key component. It is made from used plastic bottles and polyester textile waste through cleaning, pulverization, and remelting. This process not only reduces the environmental pollution caused by plastic waste but also gives polyester staple fiber new life. Recycled polyester staple fiber is widely used in clothing, home textiles, and technical fabrics, becoming a key raw material in promoting a circular economy.

Low-carbon and energy-saving production processes are gradually being adopted in the manufacturing of polyester staple fiber. By optimizing energy use and improving production equipment, manufacturers can maintain efficient production while reducing their carbon footprint, which meets the urgent need for sustainable development in the current textile industry chain.

In the future, differentiation and functionalization will become the mainstream trends in the industry. Staple fiber products with antibacterial, flame-retardant, thermal, and moisture-absorbing properties will become increasingly popular in the market. Furthermore, with growing environmental awareness, the proportion of recycled polyester staple fiber is expected to gradually increase, creating new growth points for the industry. Polyester staple fiber will continue to play a pivotal role in the textile industry, both in terms of technological innovation and market expansion.

Recycle Non-Woven Fibers Series: A New Direction for Sustainable Textiles

2025-09-22

From Fineness to Strength: A Comprehensive Analysis of the Technical Secrets and Application Potential of Denier Fiber

2025-10-08Your email address will not be published. Required fields are marked *

Focusing to the research and production of differentiated fiber. Applying recycle-material processing scientifically.

Zhulinjizhen, Xinfeng Town, Jiaxing City, Zhejiang Province

Copyright @ 2023 Jiaxing Fuda Chemical Fiber Factory All rights reserved

Polyester Staple Fiber Manufacturers

Friendship link - Anhui Fulin Environmental Protection Technology Co., Ltd.:https://www.ahflhb.com