Product Consultation

Your email address will not be published. Required fields are marked *

Polyester Staple Fiber has gradually become a key material attracting significant attention. It not only occupies an important position in the traditional textile field but also plays an increasingly prominent role in diverse industries such as home furnishings, automotive, and environmentally friendly materials. As consumers' demands for comfort, durability, and environmental performance continue to rise, the value of this type of fiber is being re-evaluated, and its technological advancements are driving the upgrading of the entire industry chain.

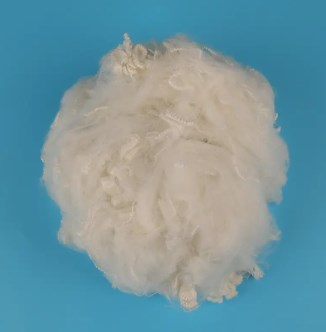

Polyester Staple Fiber typically exists in short fiber form and possesses excellent physical strength and stability. Its core structure gives the material good wear resistance, crease resistance, and shape retention capabilities, allowing it to maintain stable performance even after repeated mechanical stress. This type of fiber has relatively low moisture absorption, resulting in a refreshing feel in dry conditions and maintaining high stability in various processing techniques.

The thermoplastic structure of the material allows for more possibilities in the fiber formation and finishing stages, enabling adjustments in bulkiness, elasticity, and feel through temperature control. In the spinning and weaving process, its smooth characteristics improve processing efficiency and result in more uniform yarn formation. This controllability provides a wider range of application possibilities for downstream industries.

Polyester Staple Fiber was initially mainly used in clothing and home textiles, but with the dual development of technology and demand, its uses have extended to more comprehensive and functional fields. In the home furnishings sector, the material's stability has made it a mainstream choice in bedding, fillings, and various comfort products. In the automotive industry, its durability and deformation resistance provide irreplaceable advantages in interior materials, improving the overall stability and comfort of the vehicle.

With the rise of green manufacturing concepts, some Polyester Staple Fibers with regenerative properties have attracted further attention. The diversification of raw material sources brings greater sustainable value, providing a solid foundation for the development of environmentally friendly materials. Thanks to this environmentally friendly direction, the market demand for high-performance, high-stability short-fiber materials continues to grow, which not only broadens the industry boundaries but also brings new opportunities for companies to enhance their competitiveness.

Modern Polyester Staple Fiber technology is constantly evolving to adapt to three major trends: lightweighting, functionalization, and environmental friendliness. Lightweighting aims to reduce weight while maintaining material strength, improving user experience and reducing resource consumption. The functionalization trend involves improving the internal structure of the fiber to provide more characteristics, such as enhanced loft, improved breathability, or increased resilience, allowing the material to provide a more premium feel and comfort in applications.

The development direction towards environmental friendliness is particularly prominent. The use of recycled materials is becoming a mainstream trend, with advanced recycling technologies providing new polyester raw materials. This allows Polyester Staple Fiber to maintain stable performance while being more environmentally friendly. As consumers and businesses increasingly prioritize sustainability, this trend will be a significant driving force for the entire industry's innovation.

A: Its main advantages include high stability, strong wear resistance, good processing adaptability, and excellent molding capabilities and tactile control.

A: With the support of mature recycling and regeneration technologies, its performance can be maintained within a stable range, without affecting subsequent processing and the user experience of the final product.

A: It will mainly come from the increased demand for environmentally friendly materials, industrial functional upgrades, and the continuous demand for high-performance fibers in fields such as automotive and home furnishings.

From Raw Materials to Market: A Professional Guide to Super White Non-Woven Staple Fibers

2025-12-01

How does the Recycle Wool Spinning Fiber Series preserve the high-quality characteristics of wool while being energy-efficient and environmentally friendly?

2025-12-15Your email address will not be published. Required fields are marked *

Focusing to the research and production of differentiated fiber. Applying recycle-material processing scientifically.

Zhulinjizhen, Xinfeng Town, Jiaxing City, Zhejiang Province

Copyright @ 2023 Jiaxing Fuda Chemical Fiber Factory All rights reserved

Polyester Staple Fiber Manufacturers

Friendship link - Anhui Fulin Environmental Protection Technology Co., Ltd.:https://www.ahflhb.com