Product Consultation

Your email address will not be published. Required fields are marked *

In the field of modern textiles and nonwoven materials, Super White Non-Woven Staple Fibers are gradually becoming a focus of industry attention due to their unique properties and wide range of applications. Compared with traditional fibers, these short fibers have significant advantages in whiteness, softness, and processing performance, giving them a unique competitive edge in high-end nonwoven fabrics, medical supplies, filter materials, and high-end home textiles.

The core advantage of super white nonwoven staple fibers stems first from their high-quality raw material selection. Through refined polymerization processes and high-standard fiber bleaching treatments, the fibers achieve industry-leading whiteness. High whiteness not only enhances the visual appeal of products but also provides greater flexibility for subsequent dyeing and finishing processes, resulting in excellent color presentation and colorfastness.

In terms of production processes, super white nonwoven staple fibers utilize advanced fiber combing and opening technologies. Through precise fiber separation and uniform web formation, a high degree of fiber consistency is achieved. This process not only ensures the stability of fiber length and fineness but also optimizes the fiber distribution structure, providing a solid foundation for nonwoven fabric processing. Furthermore, modern fiber bleaching and cleaning processes effectively reduce impurities and stains, ensuring the purity and performance stability of the final product.

Ultra-white nonwoven staple fibers exhibit outstanding physical properties, with superior softness, bulkiness, and resilience compared to ordinary staple fibers. The soft touch and excellent resilience allow for the formation of a fine and uniform fiber web structure during fabric processing, improving the durability and comfort of nonwoven fabrics. Simultaneously, the high whiteness of the fiber substrate provides an ideal base color for dyeing, printing, and other post-processing techniques, resulting in superior color saturation and visual appeal in the finished product.

In terms of functionality, ultra-white nonwoven staple fibers demonstrate excellent moisture absorption and breathability, effectively regulating internal humidity and airflow. This characteristic is particularly important in medical protective equipment, infant products, and high-end home textiles, enhancing user experience and safety. The high uniformity of its fiber structure also makes it outstanding in filter materials and industrial applications, meeting high standards for filtration efficiency and durability.

With the continuous expansion of nonwoven material applications, the market demand for ultra-white nonwoven staple fibers is showing a steady growth trend. In the medical industry, its high purity and softness make it the preferred material for key products such as disposable surgical gowns, masks, and medical pads. In the high-end home textile market, ultra-white staple fibers add higher market value to products by enhancing fabric texture and feel. Meanwhile, its uniformity and durability also bring significant advantages in industrial filtration, building insulation, and functional packaging materials.

From a supply chain perspective, the production of ultra-white nonwoven staple fibers not only promotes the technological upgrading of raw material suppliers but also drives innovation in nonwoven fabric processing equipment and dyeing and finishing processes. A stable supply of high-quality fibers provides technical support for the diversified development of nonwoven products, making the entire industry more competitive in terms of quality improvement and functional innovation.

In the future, the development of ultra-white nonwoven staple fibers will continue to move towards high performance, environmental friendliness, and multifunctionality. As consumer demand for health, comfort, and functional products increases, fiber softness, antibacterial properties, and biodegradability will become key research and development focuses. Simultaneously, the application of green production processes and low-energy bleaching technologies will drive the industry towards sustainable development.

In terms of technological innovation, new fiber modification technologies and composite processes will further expand the application scenarios of ultra-white staple fibers. For example, through nano-coatings or composite fiber structures, materials can be endowed with stronger waterproof, stain-resistant, and antibacterial functions, thereby meeting the high-end needs of multiple fields such as medical, home, and industrial applications. This trend not only increases product added value but also promotes the development of the nonwoven materials industry towards high-end and intelligent directions.

Ultra-white nonwoven staple fibers occupy an important position in the nonwoven materials market due to their superior whiteness, softness, and functionality. Whether in medical protective equipment, high-end home textiles, or industrial filtration, their performance advantages and application value are fully demonstrated. Looking ahead, with technological innovation and increasingly stringent environmental requirements, ultra-white nonwoven staple fiber will continue to lead the upgrading and development of the nonwoven materials industry, providing reliable support for more high-end applications.

Through continuous optimization of production processes and expansion of application scenarios, ultra-white nonwoven staple fiber not only meets the market's demand for high-quality materials but also provides solid support for the sustainable development of the entire industry.

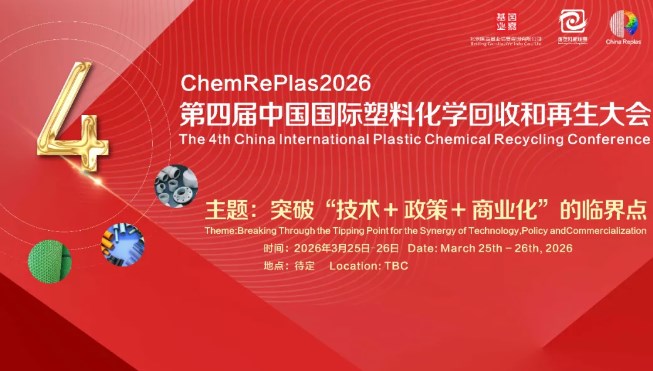

Warning of a major reshuffle! The plastic recycling industry is nearing its "suffocation point"

2025-12-04

Polyester Staple Fiber: A Core Material in the Era of High-Performance Fibers

2025-12-08Your email address will not be published. Required fields are marked *

Focusing to the research and production of differentiated fiber. Applying recycle-material processing scientifically.

Zhulinjizhen, Xinfeng Town, Jiaxing City, Zhejiang Province

Copyright @ 2023 Jiaxing Fuda Chemical Fiber Factory All rights reserved

Polyester Staple Fiber Manufacturers

Friendship link - Anhui Fulin Environmental Protection Technology Co., Ltd.:https://www.ahflhb.com