Product Consultation

Your email address will not be published. Required fields are marked *

With the continuous improvement of global environmental awareness, sustainable development has become an important goal of all walks of life, and the textile industry is no exception. Against this background, the Recycle Hollow Fibers Series came into being. As an innovative material in the textile industry, it not only greatly reduces resource consumption, but also makes positive contributions to environmental protection.

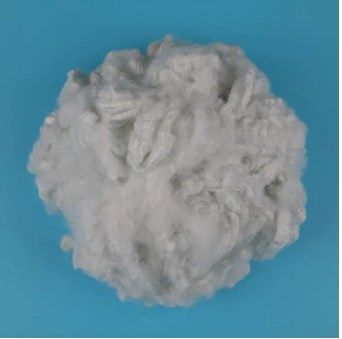

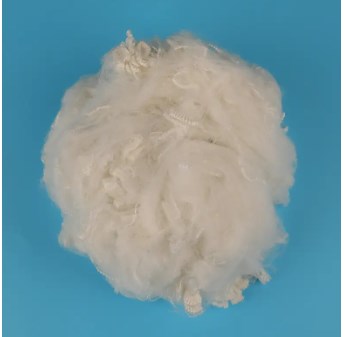

What is recycled hollow fiber?

Recycled hollow fiber is a fiber material with a hollow structure formed by recycling and reprocessing waste materials or plastics as raw materials. The internal hollow structure of the hollow fiber gives it stronger thermal insulation, heat insulation, breathability and other properties, so it is widely used in various high-performance textiles.

The production process of this series of fibers can not only effectively utilize waste materials and reduce environmental pollution, but also provide better functionality and comfort for textiles. Through this innovative application of recycled materials, recycled hollow fibers have become an excellent material that is both environmentally friendly and practical.

Advantages of recycled hollow fibers

Environmental protection and sustainability

The production process of recycled hollow fibers greatly reduces the generation of plastic waste. By recycling waste plastics, the demand for new raw materials is reduced, carbon emissions are reduced, and the problem of global resource shortages and environmental pollution is alleviated. Through recycling and reuse, recycled hollow fibers are in line with the concept of sustainable development and promote the development of a green economy.

Excellent thermal insulation performance

The unique hollow structure of hollow fibers can effectively block heat loss, which makes it particularly good in thermal insulation. Whether in winter clothing, outdoor equipment, or building insulation materials, recycled hollow fibers can play a vital role.

Lightweight and efficient

Recycled hollow fibers not only have high strength, but also have a relatively light texture due to their hollow design. This allows it to maintain excellent performance and effectively reduce the burden on the wearer when manufacturing sportswear, outdoor equipment, and medical devices.

Excellent breathability

The hollow structure of hollow fibers gives it good breathability, which helps to improve the wearing experience, especially in sportswear and summer clothing, it can effectively wick away sweat, keep the skin dry, and improve comfort.

Waterproof and antibacterial properties

Modern recycled hollow fiber materials are often specially treated to have waterproof and antifouling functions, while also increasing antibacterial properties. In the fields of medical care, outdoor use, etc., they can especially play their advantages of antibacterial, deodorizing and keeping clean.

Application fields of recycled hollow fibers

Clothing field

One of the most common applications of recycled hollow fibers is the manufacture of high-performance clothing, especially in winter clothing and sportswear. Its excellent thermal insulation and breathability make it an ideal material for down jackets, thermal underwear, outdoor cold-proof equipment, etc. Due to its lightness and comfort, recycled hollow fibers are also widely used in the manufacture of sports equipment such as sports shoes and running clothes.

Home and decoration

In the home field, recycled hollow fibers can be used as insulation materials in the manufacture of products such as mattresses, pillows, sofas and curtains. It is light, comfortable and has natural thermal insulation functions, which can improve the quality of home products and also meet consumers' demand for environmentally friendly materials.

Construction and insulation materials

The thermal insulation properties of recycled hollow fibers are widely used in the construction industry. Especially in the insulation of walls, roofs, doors and windows of buildings, recycled hollow fibers can not only effectively improve energy efficiency, but also provide longer-lasting insulation effects for buildings, reducing energy consumption for air conditioning and heating.

Medical and Health

In the medical field, recycled hollow fibers are used in the outer packaging of medical devices, textiles and care products. For example, they are used to prepare disposable sanitary napkins, masks and antibacterial fabrics, and their antibacterial and comfort properties are key factors in their widespread use.

Future Outlook: Innovative Development of Recycled Hollow Fibers

With the increasingly stringent environmental protection policies, global consumers' demand for environmentally friendly products is gradually increasing, and the market prospects for recycled hollow fibers are broader. In addition to the expansion of traditional application areas, recycled hollow fibers will also find new application space in emerging industries such as smart wearable devices, automotive interiors, and green building materials. With the continuous advancement of technology, recycled hollow fibers will not only be limited to the textile field in the future. Its innovative hollow structure and environmental advantages will make it an important material that cannot be ignored in all walks of life.

Super White Non-Woven Staple Fibers: The core material for creating high-end non-woven fabrics

2025-06-08

The chemical circulation industry is a major benefit! EU plans to expand the definition of "regeneration" in SUPD and PPWR

2025-06-25Your email address will not be published. Required fields are marked *

Focusing to the research and production of differentiated fiber. Applying recycle-material processing scientifically.

Zhulinjizhen, Xinfeng Town, Jiaxing City, Zhejiang Province

Copyright @ 2023 Jiaxing Fuda Chemical Fiber Factory All rights reserved

Polyester Staple Fiber Manufacturers

Friendship link - Anhui Fulin Environmental Protection Technology Co., Ltd.:https://www.ahflhb.com