Product Consultation

Your email address will not be published. Required fields are marked *

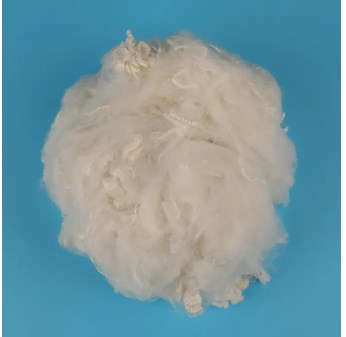

In the modern textile and non-woven fabric industry, the quality of raw materials directly determines the performance and market competitiveness of the end products. As an important basic material in the production of non-woven fabrics, Super White Non-Woven Staple Fibers are widely used in medical, sanitary, filtration, clothing lining and industrial fields due to their excellent whiteness, uniformity and environmental protection.

1. What is Super White Non-Woven Staple Fibers?

Super White Non-Woven Staple Fibers refers to short fibers with high whiteness, few impurities, uniform fiber length, and suitable for hot air, hot rolling, spunlace, needle punching and other non-woven fabric forming processes. It is usually made of polyester (PET), polypropylene (PP), viscose or other degradable raw materials (such as PLA) as the basic raw materials, and is made through processes such as opening, carding, stretching, and cutting.

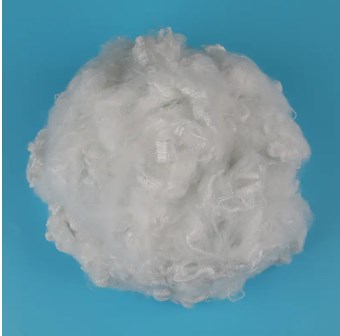

Core features include:

High whiteness index, generally ≥90 (ISO standard)

Precise fiber length control, common specifications include 38mm, 51mm, 64mm, etc.

High cleanliness, extremely low ash content

Customizable hydrophilic, water-repellent, antibacterial, flame-retardant and other functions

These features make it the first choice for non-woven fabrics for medical and health care (such as masks, wet wipes, surgical gowns), high-end filter materials and non-woven products with high aesthetic requirements.

2. The source of whiteness of ultra-white fiber: not just color

Real "ultra-white" is not simply bleaching or optical whitening, but the result of fine control of the entire process from raw materials, spinning process, cutting method, etc. Its whiteness is mainly affected by the following factors:

Purity of raw materials

The selection of high molecular weight, high purity PET or PP raw materials and the elimination of recycled materials are the primary conditions for ensuring whiteness.

Spinning and stretching precision

Adopt high-speed spinning and tension precision control system to avoid fiber thermal yellowing and micro-pollution.

Optical brightener application control

By adding the right type and dosage of optical brightener, the ultraviolet light reflection effect is enhanced, and the visual whiteness is further improved.

3. Multi-scenario application: popular application areas of Super White Non-Woven Staple Fibers

1. Medical and sanitary materials

Super white staple fibers are widely used in the production of medical non-woven fabrics, such as disposable surgical gowns, medical mask layers, baby wipes, adult care pads, etc. High whiteness helps to highlight the sense of hygiene and cleanliness, and meets the appearance and hygiene standards of medical products.

2. Beauty and care products

Facial mask cloths, makeup remover cotton, soft towel rolls, etc. have extremely high requirements for fabric whiteness and softness. The use of super white fibers can improve the overall product grade and enhance consumers' trust.

3. High-end filter materials

Air conditioning filters, industrial dust removal bags, etc. require non-woven fabrics with both high porosity and certain strength, and super white fibers not only guarantee performance, but also facilitate inspection of pollution and blockage.

4. Non-woven interlinings and composite materials

Clothing linings or home textile composite fabrics have strict requirements on color uniformity. Ultra-white fibers not only improve the overall texture, but also facilitate color matching with other surface materials.

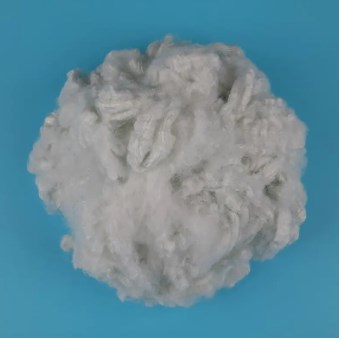

IV. Green transformation: the rise of degradable ultra-white staple fibers

As the world's attention to sustainable development and environmentally friendly materials continues to increase, traditional petrochemical-based ultra-white staple fibers have begun to transform into bio-based materials. Biodegradable raw materials such as PLA (polylactic acid) fibers, PBS, and PHA have also been introduced into ultra-white fiber production lines, which have the following advantages:

100% biodegradable and environmentally friendly

Whiteness indicators can also reach high standards

More in line with green certification requirements in Europe and the United States (such as OEKO-TEX, GOTS, FDA)

Against the backdrop of continued growth in demand for disposable non-woven products, this type of environmentally friendly ultra-white staple fiber is gradually replacing traditional materials and becoming a mainstream trend.

Super White Non-Woven Staple Fibers, as a vital basic material in the current non-woven industry chain, is constantly expanding its application boundaries in various industries. Whether it is whiteness performance, environmental protection properties, or functional potential, it provides solid support for high-quality nonwoven products. For companies committed to creating high-end, differentiated products, mastering the latest technology and market trends of ultra-white fibers is undoubtedly an important step to win the future.

Recycle Wool Spinning Fiber Series: Revolutionizing Sustainability in Textiles

2025-06-01

Recycle Hollow Fibers Series: A new textile choice for the future that improves sustainability

2025-06-15Your email address will not be published. Required fields are marked *

Focusing to the research and production of differentiated fiber. Applying recycle-material processing scientifically.

Zhulinjizhen, Xinfeng Town, Jiaxing City, Zhejiang Province

Copyright @ 2023 Jiaxing Fuda Chemical Fiber Factory All rights reserved

Polyester Staple Fiber Manufacturers

Friendship link - Anhui Fulin Environmental Protection Technology Co., Ltd.:https://www.ahflhb.com