Product Consultation

Your email address will not be published. Required fields are marked *

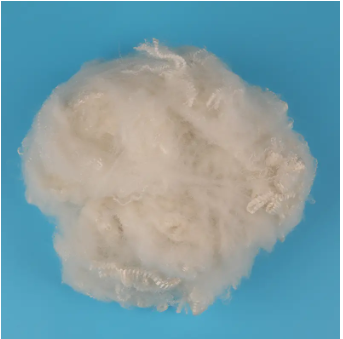

In an era where environmental consciousness is at the forefront of global discussions, the textile industry is under increasing scrutiny for its ecological footprint. Among the various initiatives to make the industry more sustainable, the recycle wool spinning fiber series has emerged as a game - changer. Wool, a natural fiber with a long - standing reputation for warmth, durability, and comfort, has been a staple in the textile world for centuries. However, the traditional production of wool, from sheep farming to the manufacturing of finished products, has significant environmental implications, including high water usage, land degradation, and methane emissions from sheep.

The recycle wool spinning fiber series offers a sustainable alternative. By recycling post - consumer and post - industrial wool waste, this innovative approach not only reduces the need for virgin wool production but also minimizes the amount of textile waste that ends up in landfills or incinerators.

The Production Process of Recycle Wool Spinning Fiber

Collection of Wool Waste

The first step in the production of recycle wool spinning fiber is the collection of wool waste. This waste can come from various sources. Post - consumer waste includes discarded woolen garments, such as sweaters, coats, and scarves, which are donated to thrift stores, recycling centers, or collected through textile recycling programs. Post - industrial waste, on the other hand, consists of off - cuts, trimmings, and defective products from textile mills and clothing manufacturers.

Advanced sorting technologies are employed at this stage to separate wool from other materials in the waste stream. Near - infrared (NIR) spectroscopy is one such technology that can quickly and accurately identify the fiber composition of mixed waste. By shining NIR light on the materials, different fibers absorb and reflect the light in unique patterns, allowing for precise sorting.

Cleaning and Preparation

Once the wool waste has been collected and sorted, it undergoes a thorough cleaning process. This is essential to remove dirt, stains, oils, and any other contaminants that may be present. The cleaning methods used depend on the nature of the waste and the intended end - use of the recycled fiber.

For lightly soiled wool, a simple washing process with mild detergents and water may be sufficient. However, for more heavily soiled or stained items, additional treatments such as enzymatic cleaning or dry cleaning techniques may be required. After cleaning, the wool is dried and then mechanically processed to open up the fibers and remove any tangles or mats. This may involve passing the wool through carding machines, which use wire - covered cylinders to comb and align the fibers.

Fiber Reclamation

The fiber reclamation stage is where the recycled wool is transformed into a usable form for spinning. There are two main methods for fiber reclamation: mechanical and chemical.

Mechanical reclamation is the more common and environmentally friendly method. In this process, the cleaned and prepared wool waste is fed into specialized machinery that breaks down the fibers through a series of mechanical actions, such as tearing, cutting, and combing. The goal is to separate the individual fibers and make them suitable for spinning. Carding and teasing machines are often used at this stage to further open up and align the fibers.

Chemical reclamation, while less frequently used, can be effective for certain types of wool waste. This method involves using chemical solvents or treatments to dissolve or break down the wool fibers and then reform them into a new fiber structure.

Blending and Spinning

After the fiber reclamation process, the recycled wool fibers are often blended with other fibers, either recycled or virgin, to achieve specific properties in the final yarn. Common blending partners for recycled wool include recycled polyester, which can add strength and durability, and natural fibers like cotton or linen, which can enhance breathability and softness.

The blending ratio is carefully determined based on the desired characteristics of the yarn. For example, if a soft and warm yarn for a winter sweater is desired, a higher proportion of recycled wool may be used, perhaps blended with a small amount of recycled cashmere for added luxury. Once the fibers are blended, they are spun into yarn using traditional spinning techniques. These can include ring spinning, which is known for producing high - quality, smooth yarns, or open - end spinning, which is faster and more suitablefor coarser yarns.

Applications of Recycle Wool Spinning Fiber Series

Apparel Industry

Outerwear: Recycle wool spinning fiber is widely used in the production of outerwear such as coats and jackets. The natural insulating properties of wool, combined with the durability added by possible blending with other fibers, make it an ideal choice for keeping warm in cold weather. Brands are now creating stylish, sustainable coats made from recycled wool that not only look good but also have a reduced environmental impact compared to traditional outerwear.

Knitwear: Sweaters, scarves, and hats are staple items in the knitwear category that can be made from recycled wool. The softness and texture of recycled wool make it comfortable to wear against the skin, and the ability to blend it with other fibers allows for a wide range of design possibilities. From chunky, rustic - looking sweaters to fine - gauge, elegant scarves, recycled wool knitwear is becoming increasingly popular among consumers who value both style and sustainability.

Underwear and Base Layers: Although less common than in outerwear and knitwear, recycled wool is also being used in the production of underwear and base layers. Wool's natural moisture - wicking properties help keep the body dry, and its antibacterial nature can reduce odors, making it suitable for close - to - skin wear. By using recycled wool in these products, manufacturers can offer consumers a sustainable option for their everyday clothing needs.

Home Textiles

Bedding: Wool has long been valued for its warmth and comfort, and recycled wool is now finding its way into bedding products. Mattress toppers, pillows, and blankets made from recycled wool can provide a cozy and sustainable sleep environment. The natural breathability of wool helps regulate body temperature, preventing overheating during sleep, and the recycled aspect of the fiber appeals to environmentally conscious consumers.

Upholstery: In the world of interior design, upholstery fabrics play a crucial role. Recycled wool is an excellent choice for upholstering furniture such as sofas, armchairs, and ottomans. It is durable enough to withstand daily use, and its natural texture can add a touch of elegance to any room. The fact that it is made from recycled materials aligns with the growing trend towards sustainable interior design.

Rugs and Carpets: Wool rugs and carpets are known for their softness, durability, and ability to add warmth and style to a space. Recycled wool can be used to create beautiful, eco - friendly rugs and carpets. These products not only reduce the environmental impact associated with traditional wool production but also offer a unique look and feel. The variety of colors and patterns that can be achieved with recycled wool makes it suitable for a wide range of interior design styles.

Industrial and Technical Applications

Filtration Materials: Wool's natural ability to trap particles and filter out impurities makes recycled wool a suitable material for industrial filtration applications. It can be used in air filters, water filters, and oil filters. In air filtration systems, for example, recycled wool filters can effectively capture dust, pollen, and other airborne contaminants, improving air quality. The use of recycled wool in filtration materials also reduces the need for synthetic materials, which are often derived from non - renewable resources.

Insulation: In the construction and automotive industries, insulation materials are essential for energy efficiency. Recycled wool can be used as an insulating material due to its low thermal conductivity. It can be installed in walls, roofs, and floors of buildings to help retain heat in winter and keep the interior cool in summer. In the automotive industry, recycled wool insulation can be used in vehicle cabins to improve energy efficiency and reduce noise levels.

Benefits of Recycle Wool Spinning Fiber Series

Environmental Benefits

Reduction of Waste: By recycling wool waste, the recycle wool spinning fiber series diverts a significant amount of textile waste from landfills and incinerators. According to the Environmental Protection Agency (EPA), the textile industry is responsible for a large portion of solid waste in the United States, with millions of tons of clothing and textiles being discarded each year. Using recycled wool helps to close the loop in the textile life cycle, reducing the overall waste generated by the industry.

Conservation of Resources: Recycling wool reduces the need for virgin wool production. Virgin wool production requires significant resources, including land for sheep farming, water for processing, and energy for shearing, transportation, and manufacturing. By using recycled wool, these resources can be conserved. Additionally, the use of recycled fibers in general reduces the demand for raw materials such as oil (in the case of synthetic fibers) and new plant - based fibers, which helps to preserve natural habitats and reduce the environmental impact associated with resource extraction.

Lower Carbon Footprint: The production of recycled wool generally has a lower carbon footprint compared to virgin wool production. The energy required to recycle wool is significantly less than that needed to produce new wool from scratch. Sheep farming, a major part of virgin wool production, is a significant emitter of methane, a potent greenhouse gas. By reducing the reliance on virgin wool, the recycle wool spinning fiber series helps to mitigate climate change by reducing greenhouse gas emissions.

Economic Benefits

Job Creation: The recycle wool spinning fiber series creates jobs throughout the supply chain. From the collection and sorting of wool waste to the production of recycled fiber and the manufacturing of finished products, there are opportunities for employment in various sectors. Local communities can benefit from the establishment of recycling facilities and small - scale textile manufacturing businesses that focus on using recycled wool. This not only provides economic opportunities but also helps to develop skills in the recycling and textile industries.

Cost - Savings: In some cases, using recycled wool can be more cost - effective than using virgin wool. The cost of raw materials for recycled wool is often lower, as it is sourced from waste materials that would otherwise be discarded. Additionally, as the demand for sustainable products grows, there is a potential for increased market share and customer loyalty for companies that use recycled wool in their products. This can lead to long - term cost - savings through economies of scale and improved brand reputation.

Social Benefits

Promotion of Sustainable Living: The availability of products made from recycle wool spinning fiber series promotes sustainable living among consumers. When people choose to purchase recycled wool products, they are making a conscious decision to support a more sustainable future. This can lead to a greater awareness of environmental issues and encourage others to make similar choices in their daily lives.

Animal Welfare Considerations: By reducing the demand for virgin wool, the recycle wool spinning fiber series can have a positive impact on animal welfare. The intensive sheep farming practices associated with large - scale virgin wool production can sometimes involve ethical concerns, such as over - shearing and poor living conditions for the animals. By using recycled wool, consumers can support a more sustainable and ethical approach to textile production that may reduce the pressure on sheep farming operations.

Challenges in the Recycle Wool Spinning Fiber Series

Quality Control

Inconsistent Fiber Quality: One of the main challenges in working with recycled wool is the inconsistent quality of the fibers. Wool waste can come from a variety of sources, and the fibers may have different lengths, thicknesses, and degrees of wear. This can make it difficult to produce a consistent - quality yarn. For example, if the recycled wool contains a high proportion of short or damaged fibers, it can lead to weak spots in the yarn and affect the overall strength and durability of the final product.

Color and Dyeing Issues: Recycled wool may already be dyed in a variety of colors, which can pose challenges when trying to achieve a specific color in the final product. Removing the existing dyes from recycled wool can be a complex and resource - intensive process, and in some cases, it may not be possible to completely remove the color. This can limit the color options available for products made from recycled wool or require more creative approaches to dyeing, such as using natural dyes or blending different colored recycled fibers to create unique color combinations.

Scale and Infrastructure

Limited Collection and Recycling Infrastructure: The success of the recycle wool spinning fiber series depends on an efficient collection and recycling infrastructure. Currently, in many regions, the infrastructure for collecting and recycling wool waste is still underdeveloped. There may be a lack of convenient collection points for consumers to drop off their woolen items, and the recycling facilities may not have the capacity or technology to handle large volumes of wool waste. This can limit the availability of recycled wool and increase the cost of production.

Scaling Up Production: As the demand for recycled wool products grows, there is a need to scale up production. However, scaling up can be challenging due to the limitations of the existing infrastructure and the technical difficulties associated with processing large volumes of wool waste. Manufacturers may need to invest in new equipment and technology to increase their production capacity, which can be costly. Additionally, ensuring a consistent supply of high - quality recycled wool at a large scale can be a logistical challenge.

Consumer Perception

Perceived Inferiority: Some consume

rs may perceive recycled wool products as being of lower quality compared to products made from virgin wool. This perception may be based on the idea that recycled materials are second - hand or not as good as new. In reality, with proper processing and quality control, recycled wool can be just as good, if not better, in terms of performance and durability. However, changing this consumer perception requires education and marketing efforts to highlight the benefits of recycled wool and the high - quality products that can be made from it.

Lack of Awareness: Many consumers are still not aware of the recycle wool spinning fiber series and the environmental and social benefits it offers. There is a lack of public education about the importance of recycling wool and the availability of recycled wool products in the market. This lack of awareness can limit the demand for recycled wool products and slow down the growth of the sustainable textile industry.

Future Prospects of Recycle Wool Spinning Fiber Series

Technological Advancements

Improved Recycling Technologies: The future of the recycle wool spinning fiber series looks promising with the development of new and improved recycling technologies. Researchers are constantly working on ways to make the recycling process more efficient, reduce the environmental impact, and improve the quality of the recycled fiber. For example, new chemical and mechanical processes may be developed to better separate wool from other materials in mixed waste, resulting in a higher - quality recycled wool product.

Smart and Sustainable Fibers: There is also potential for the development of smart and sustainable fibers based on recycled wool. These fibers could have additional functionalities, such as self - cleaning properties, temperature regulation, or the ability to release beneficial substances like vitamins or antioxidants. By combining the sustainability of recycled wool with these advanced features, the textile industry could offer a new generation of products that meet the evolving needs of consumers.

Market Growth

Increasing Consumer Demand: As consumers become more environmentally conscious, the demand for sustainable textile products, including those made from recycled wool, is expected to grow. Consumers are now more willing to pay a premium for products that are eco - friendly and have a lower carbon footprint. This growing demand will drive the expansion of the recycle wool spinning fiber series market, leading to more product innovation and a wider availability of recycled wool products.

Industry Collaboration: The textile industry is likely to see increased collaboration among different stakeholders to promote the use of recycled wool. Brands, manufacturers, recyclers, and retailers may work together to create a more sustainable supply chain. For example, brands may partner with recycling companies to ensure a reliable supply of high - quality recycled wool, and retailers may play a role in educating consumers about the benefits of recycled wool products. This collaboration will help to overcome the challenges facing the recycle wool spinning fiber series and accelerate its growth in the market.

Conclusion

The recycle wool spinning fiber series represents a significant step forward in the pursuit of sustainability in the textile industry. By recycling wool waste and transforming it into valuable fibers for spinning, this innovative approach offers numerous environmental, economic, and social benefits. From reducing waste and conserving resources to creating jobs and promoting sustainable living, the recycle wool spinning fiber series has the potential to revolutionize the way we produce and consume textiles.

Looking to the future, with technological advancements and increasing consumer demand, the recycle wool spinning fiber series is poised for significant growth. It has the potential to become a mainstream option in the textile market, replacing traditional virgin wool production in many applications. As the world continues to grapple with environmental issues, the recycle wool spinning fiber series offers a practical and sustainable solution that benefits both the planet and its inhabitants.

Recycle Wool Spinning Fiber Series: A new chapter in sustainable fashion

2025-05-22

Super White Non-Woven Staple Fibers: The core material for creating high-end non-woven fabrics

2025-06-08Your email address will not be published. Required fields are marked *

Focusing to the research and production of differentiated fiber. Applying recycle-material processing scientifically.

Zhulinjizhen, Xinfeng Town, Jiaxing City, Zhejiang Province

Copyright @ 2023 Jiaxing Fuda Chemical Fiber Factory All rights reserved

Polyester Staple Fiber Manufacturers

Friendship link - Anhui Fulin Environmental Protection Technology Co., Ltd.:https://www.ahflhb.com