Product Consultation

Your email address will not be published. Required fields are marked *

The traditional linear development model of the textile industry has reached the dual turning point of ecological environment and economy, and the new textile economy based on circular economy is rapidly emerging. The T2T (Textile to Textile, from textile to textile) recycling model has become the key to systemic change in the industry and is reconstructing the industry ecology.

This article not only introduces the generation of waste textiles around the world, but also analyzes the development environment of T2T from the perspective of policy supervision and support and market demand in China, Europe, the United States, South Korea and other countries and regions, and shares the goals and practices of recycled materials use by brands such as Nike and H&M, in order to outline a T2T development blueprint for readers.

1. Textile industry’s linear dilemma and T2T breakthrough logic

As one of the pillar industries of the global economy, the environmental footprint of the textile industry cannot be ignored. The industry contributes approximately 3% of global greenhouse gas emissions. 1 . At the same time, the global textile industry is facing severe waste challenges, generating more than 9,200 tons of textile waste every year, which is equivalent to a garbage truck full of clothes being sent to a landfill or incineration plant every second. 2 . Currently, only 1% of the world’s used clothing can be recycled into new clothes. 3 , the vast majority face the end of landfill, incineration or low-value downgrading.

The traditional linear model of "resource consumption - product production - use and discard" will not only exacerbate the contradiction between overcapacity and resource shortage, but also cause serious environmental burdens on the earth. The carbon emissions of the textile industry run through the entire industry chain, which makes the circular economy an inevitable choice for high-quality development, and the T2T model is the core force in promoting the green transformation of the industry.

In this context, from textiles to textiles The (Textile to Textile, T2T) recycling model has become the key to systemic changes in the industry and is reconstructing the industry ecology.

T2T from textiles to textiles

T2T converts waste textiles into recycled fibers through physical or chemical technology and reuses them for textile production. It is different from traditional low-value recycling such as downgrading and utilization, and is an important direction for the sustainable development of the textile industry. This model can not only effectively digest excess production capacity and reshape the production cycle of the textile industry, but also reduce resource consumption and pollutant emissions from the source. Data from the Bureau of International Recycling (BIR) shows that for every kilogram of waste textiles properly utilized, greenhouse gas emissions can be reduced by 3.6kg CO₂ equivalent and 6,000L of water resources can be saved. With the development and large-scale application of recycling technology, it is expected that the global fiber T2T recycling ratio is expected to increase to 26% by 2030 4 , showing huge development potential.

2. Global textile recycling policy: institutional driving force for T2T development

Countries and regions have introduced policies related to textile recycling and reuse, and have put forward clear requirements for the recycling rate of waste textiles and the output of recycled fiber, etc., building a policy support system for the T2T model, and relevant industry standards have also been implemented to promote the transformation of the textile industry into a dual-driven transformation of environmental benefits and economic benefits.

--China

As the world's largest producer and consumer of textiles and clothing, my country's annual waste textile production in 2023 will be approximately 23.3 million tons, with actual utilization of approximately 5.53 million tons. Carbon emissions can be reduced by approximately 19.91 million tons through recycling. 5 .

In April 2022, the National Development and Reform Commission, the Ministry of Commerce, and the Ministry of Industry and Information Technology jointly issued the "Implementation Opinions on Accelerating the Recycling of Waste Textiles" (Fagaihuanzi [2022] No. 526), clarifying:

● By 2025, the waste textile recycling system will be initially established, the waste textile recycling rate will reach 25%, and the output of waste textile recycled fiber will reach 2 million tons.

● By 2030, a relatively complete waste textile recycling system will be established, high-value utilization channels will continue to expand, the level of industrial development will be significantly improved, the waste textile recycling rate will reach 30%, and the output of recycled fiber from waste textiles will reach 3 million tons.

● Improve the waste textile recycling network and promote brand companies to increase the proportion of recycled fiber use.

National standards such as "Technical Specifications for Recycling of Waste Textiles" and "Technical Specifications for Recycling of Waste Textiles" have been released successively, and carbon emission-related group standards such as "Carbon Emission Accounting and Reporting Requirements for Waste Textile Recycling Enterprises" have been continuously enriched.

——European Union

The impact of EU textile consumption on the environment and climate change ranks fourth on average, after food, housing and transportation. The amount of clothing discarded every year weighs 5 million tons, or 12 kilograms per person. 6 .Based on the European Green Deal, the EU has formulated a series of textile related policies and regulations to empower consumers and constrain production and sales to reduce the impact of textiles on the environment and climate.

● The "Circular Economy Action Plan" stipulates that textiles that do not meet the definition of sustainability will not be sold in Europe and requires products sold in Europe to disclose environmental information such as carbon footprints.

● The "Sustainable and Circular Textiles Strategy" focuses on the entire life cycle of textile products and proposes that textiles put on the EU market by 2030 should be durable, repairable, recyclable, and come from recycled fibers to a large extent. In addition, textiles are also required to have a Digital Product Passport (DPP) and provide sufficient sustainability information, such as environmental footprints such as carbon footprints.

● "Sustainable Product Ecological Design" stipulates that products must comply with ecological design requirements before they can enter the EU market for circulation or put into use. Its purpose is to improve the environmental sustainability of products and reduce the overall carbon footprint and environmental footprint of the product during its life cycle.

● The "Waste Framework Directive" requires member states to establish a textile classification collection system before January 1, 2025, and promote the establishment of an extended producer responsibility (EPR) system to provide a stable source of funds for textile recycling and T2T regeneration.

● The "Textile Labeling Regulations" require that textiles must be labeled or marked to indicate key information when they are sold on the market. The EU plans to propose amendments to the regulation in the third quarter of 2025, which will pay special attention to environment-related information.

Some EU member states have proposed clear reuse and recycling ratio targets, the most representative of which are the Netherlands and France:

——Dutch textile EPR target

By 2025:

1) At least 50% of the textiles put on the market in the previous year must be prepared for reuse or recycling (preparation for re-use and recycling), and this proportion needs to increase by 5% every year, reaching 75% by 2030;

2) At least 20% of recycled textiles must be reused, and this proportion needs to increase by 1% every year to reach 25% by 2030;

3) At least 10% of reused textiles must be used in products sold in the Netherlands, and this proportion needs to increase by 1% every year to reach 15% by 2030;

4) 25% of textile fibers from waste textiles must be used for T2T, reaching 33% by 2030.

——French textile EPR target

As the first country in the world to implement the EPR system in the textile field, France is constrained by regulations such as the Environmental Code and the Anti-Waste Law, covering multiple dimensions such as recycling targets, regeneration standards, and full-chain responsibility. The system is currently coordinated and implemented by Refashion, the only textile producer responsibility organization (PRO). In the new round of government approval documents from 2023 to 2028, specific goals have been clarified. 7 :

1) By 2028, the recycling rate of waste textiles, clothing and footwear (TLC) will reach 60%;

2) By 2027, at least 15% of waste textiles suitable for reuse will be disposed of locally to reduce waste exports;

3) By 2027, the recycling rate of used TLC that has not been reused will reach 80%.

--USA

According to data released by the U.S. sustainability consultant Resource Recovery System (RRS), the growth of textile waste has exceeded that of other major wastes, and some states have introduced legislative constraints on textile recycling. For example, California passed the Responsible Textile Recovery Act of 2024, becoming the first state in the United States to have an EPR law specifically targeting clothing and textiles, requiring producers to join the Producer Responsibility Organization PRO and assume responsibility for the recycling, sorting and reuse of post-consumer textiles.

——South Korea

The "Enforcement Order of the Special Taxation Restriction Law" clearly stipulates that tax deductions and other incentive policies will be provided to specific operators of "renewable waste resources". Waste fiber, along with scrap steel, waste tires, waste oil, etc., are clearly included in "renewable waste resources". In addition, South Korea has included "waste fiber chemical and biological regenerated fiber material manufacturing technology" into the "new growth source technology" catalog. Related R&D R&D investments can enjoy a significantly higher tax credit ratio than general R&D, that is, 30-40% for small and medium-sized enterprises and 20-30% for medium and large enterprises. This move can effectively promote the development of the T2T industry through tax exemption incentives.

The core orientation of these national and regional policies points to the T2T development model, which is to establish a high-value reuse system based on high recycling rates. Through institutional constraints and policy incentives, all links in the industry chain are forced to increase investment and clear obstacles for the large-scale development of T2T.

3. Chain owner enterprise actions: the core strength of T2T market-driven

As consumers' awareness of green consumption increases, the low-carbon cycle and sustainable development of the entire textile and apparel industry will also usher in greater market driving force. Chain master brands such as Nike, Inditex, and H&M have targeted the use of recycled materials, forcing the upstream to accelerate T2T technology iteration and production capacity layout. The entire chain of recycling, regeneration, and application will work together to transform the closed-loop model of "waste into new raw materials" from policy orientation to industrial effectiveness.

The unique advantage of the T2T model is also reflected in its climate-friendly characteristics. Through a closed-loop cycle from textile to textile, the carbon emissions caused by the production of virgin fibers are reduced from the source. On the one hand, the chain owner's procurement of T2T materials can reduce the carbon emissions of its Scope 3 "Category 1 Outsourced Goods and Services", thereby improving its climate performance and ESG performance; on the other hand, increasing the proportion of recycled textile fibers/fabrics can help products comply with regulations and smoothly enter markets that have high requirements for recycling and reuse rates (such as the European market).

The carbon emissions generated by materials and energy used in manufacturing account for approximately 70% of Nike's total carbon footprint. Therefore, Nike regards this field as a core breakthrough to reduce environmental impact and reduces the environmental impact of its products through the adoption and large-scale application of Environmentally Friendly Priority Materials (EPMs).

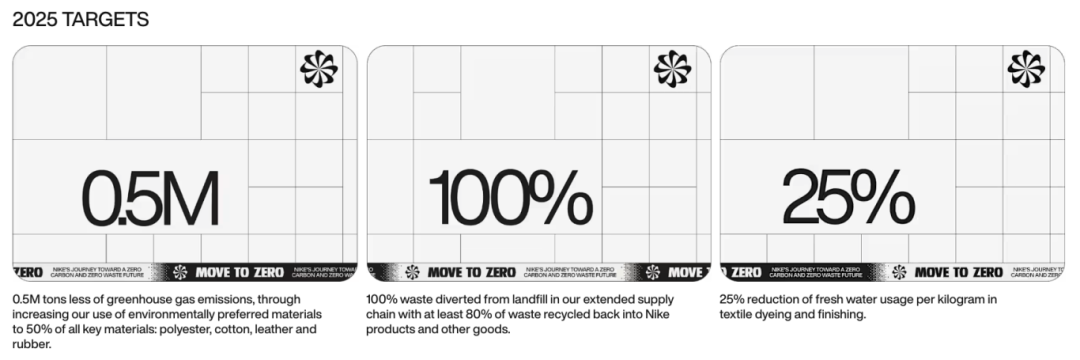

Nike not only set a carbon goal of net zero emissions in 2050, but also achieved its 2025 goal ahead of schedule, which is to reduce 500,000 tons of carbon emissions by using no less than 50% of EPMs in all key materials (polyester, cotton, leather and rubber). Measures such as increasing the proportion of recycled polyester in footwear products and optimizing low-carbon leather materials are the key to progress. Nike's fiscal year 2023 impact report shows that the proportion of recycled polyester fiber used in Nike's footwear and apparel products has increased by 11% compared with fiscal year 2022; its subsidiary Converse is also expanding the use of recycled polyester fiber and replacing virgin polyester materials with recycled polyester as much as possible in each shoe style. The brand's use of recycled polyester fiber has increased by 91% compared with the previous year.

Recently, Nike also signed multi-year offtake agreements with textile recycling companies Syre and Loop Industries. The partnership will help Syre secure financing for its first commercial-scale recycling plant in Vietnam, with the goal of achieving a production capacity of over 3 million tons by 2032.

Inditex plans to use only "low environmental impact" textile materials by 2030, of which about 40% come from recycled materials from conventional recycling processes (including T2T), 25% from next-generation materials that have not yet been industrialized (including T2T), and 25% from organic and regenerative agriculture.

Inditex has continued to increase the procurement and investment of T2T raw materials in recent years. In 2022, it made an equity investment in the start-up company CIRC (the core technology is to convert the most common polyester-cotton blend into new recycled raw materials). Based on this cooperation, in 2023 Zara cooperated with CIRC to launch the first series of products made of recycled polyester-cotton blended materials.

Inditex has also reached an agreement with Infinited Fiber, committing to purchase 30% of its future production over three years. Infinna™ is a regenerated fiber made from 100% textile waste. This purchase commitment, worth more than 100 million euros, plays a key role in Infinited Fiber's construction of its first industrial-scale factory and the expansion of its recycling technology production capacity.

H&M Group proposes that by 2030 all materials will come from recycled or sustainable sources, with a target of 50% recycled materials.

H&M is one of the most active leading brands in the field of recycled textile materials. In 2024, it reached a purchase agreement for recycled polyester with a total value of US$600 million within seven years with Syre; in 2025, it signed a multi-year strategic procurement agreement with innovative materials company Circulose, committing to large-scale procurement of its material CIRCULOSE® made of 100% recycled textile waste to gradually replace the virgin viscose fiber used extensively in its brands.

In addition to footwear and apparel brands such as Nike and Inditex, luxury brands are also constantly investing in the circular economy. For example, Chanel launched Nevold, a B2B platform for recycled materials this year, which is committed to promoting the large-scale industrialization of recycled materials and meeting the challenge of scarcity of luxury fashion raw materials.

The brand's long-term procurement commitment has become a key factor for T2T companies to obtain financing and further development, which will help these companies implement commercial-scale mass production projects, thus strengthening the supply resilience of the industrial chain.

As the market awareness of textile recycled materials continues to deepen and the scope of applications continues to expand, T2T will become a key area of the new textile economy based on circular economy. On the one hand, policies around the world continue to strengthen support and supervision for the recycling of waste textiles. On the other hand, the awareness of sustainable consumption and the responsibility leadership of brands have become key forces on the market side. Multi-party collaboration is promoting the transformation of the textile industry to a dual-driven transformation of environmental benefits and economic benefits.

Why is Flocking Polyester Tow Series the Preferred Fiber in the Textile Industry?

2025-11-22

Warning of a major reshuffle! The plastic recycling industry is nearing its "suffocation point"

2025-12-04Your email address will not be published. Required fields are marked *

Focusing to the research and production of differentiated fiber. Applying recycle-material processing scientifically.

Zhulinjizhen, Xinfeng Town, Jiaxing City, Zhejiang Province

Copyright @ 2023 Jiaxing Fuda Chemical Fiber Factory All rights reserved

Polyester Staple Fiber Manufacturers

Friendship link - Anhui Fulin Environmental Protection Technology Co., Ltd.:https://www.ahflhb.com