Established in 1995, Jiaxing Fuda Chemical Fiber Factory is located in the heartland of Yangtze River Delta. The company is located less than 100 kilometers far away from Shanghai,Hangzhou, Ningbo and Suzhou. with good location and convenient water and land transportation.

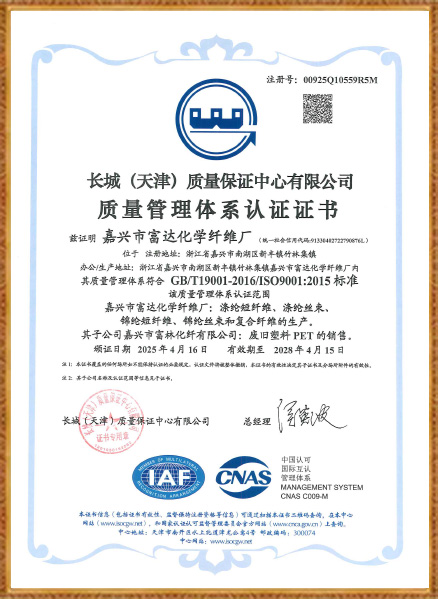

Through 20 years of development, we have 4 production lines for component fiber and 7 production lines for recycled polyester staple fiber with international advanced technologies and processes, with annual output of 40,000 tons component staple fiber . 110,000 tons polyester fiber and 10,000 tons electrostatic flocking tow.

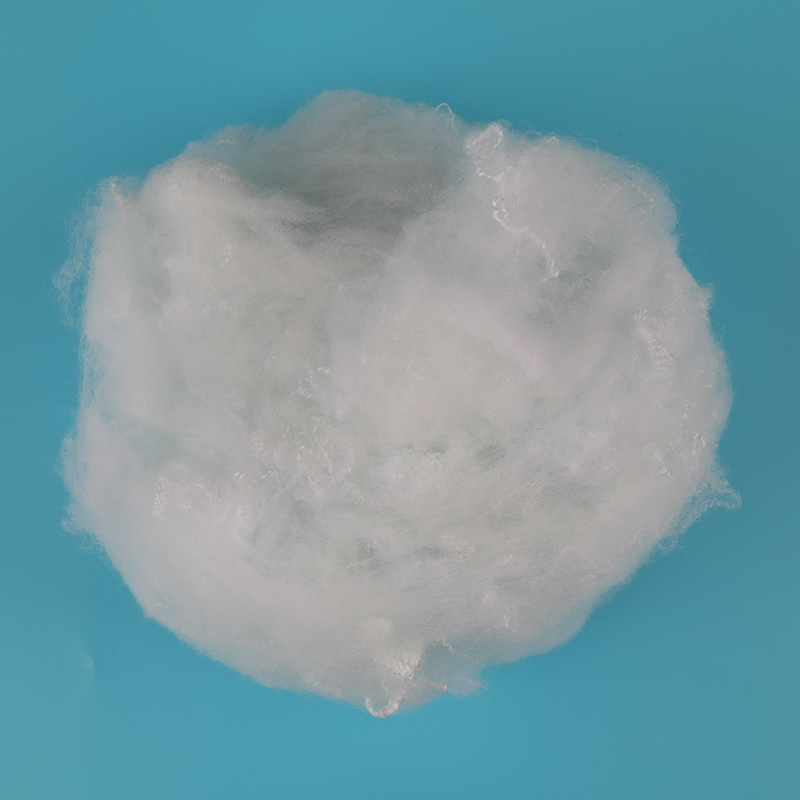

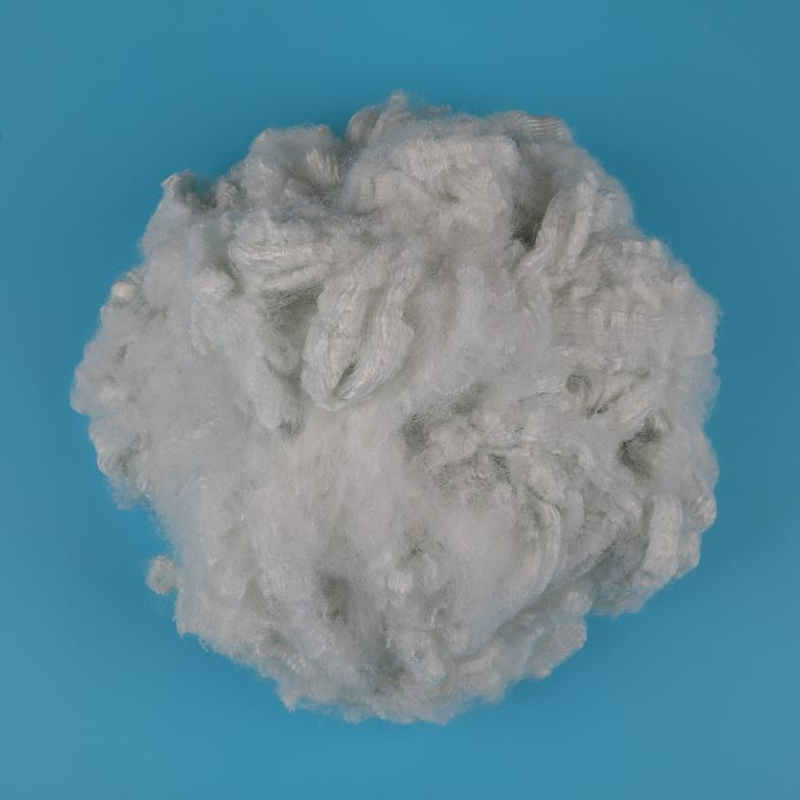

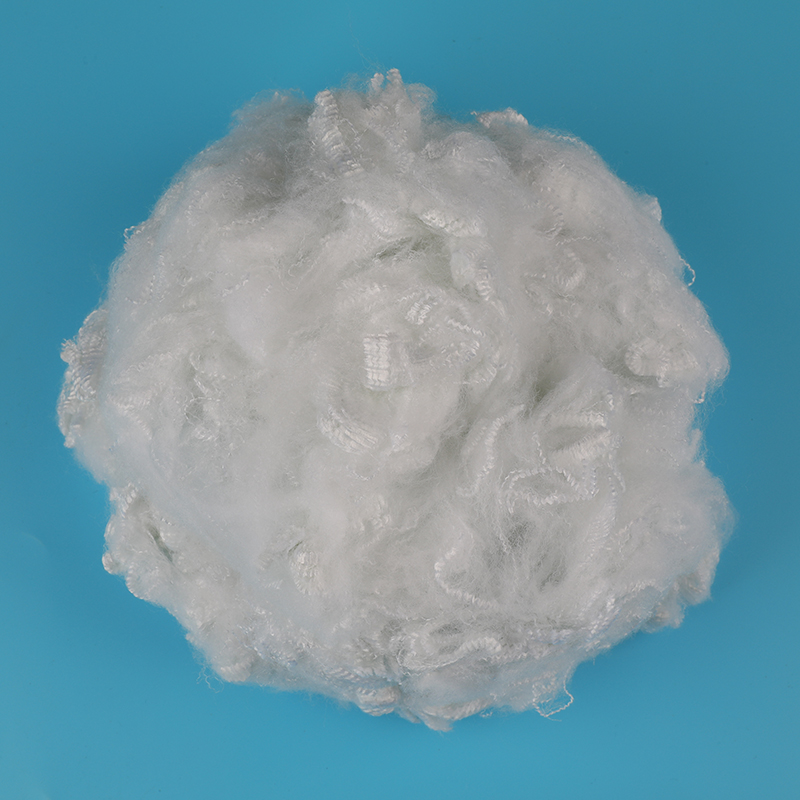

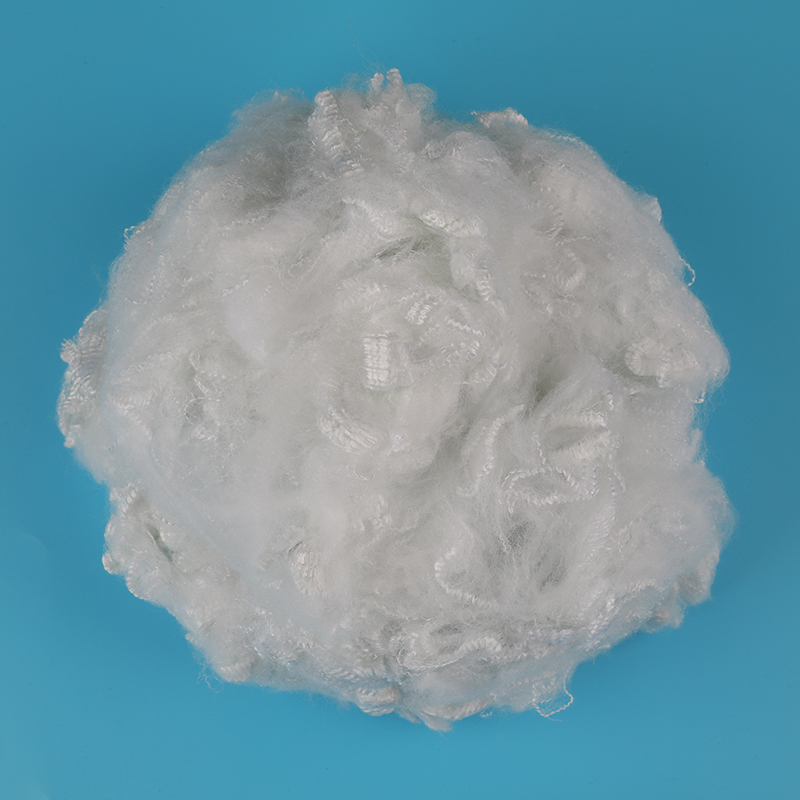

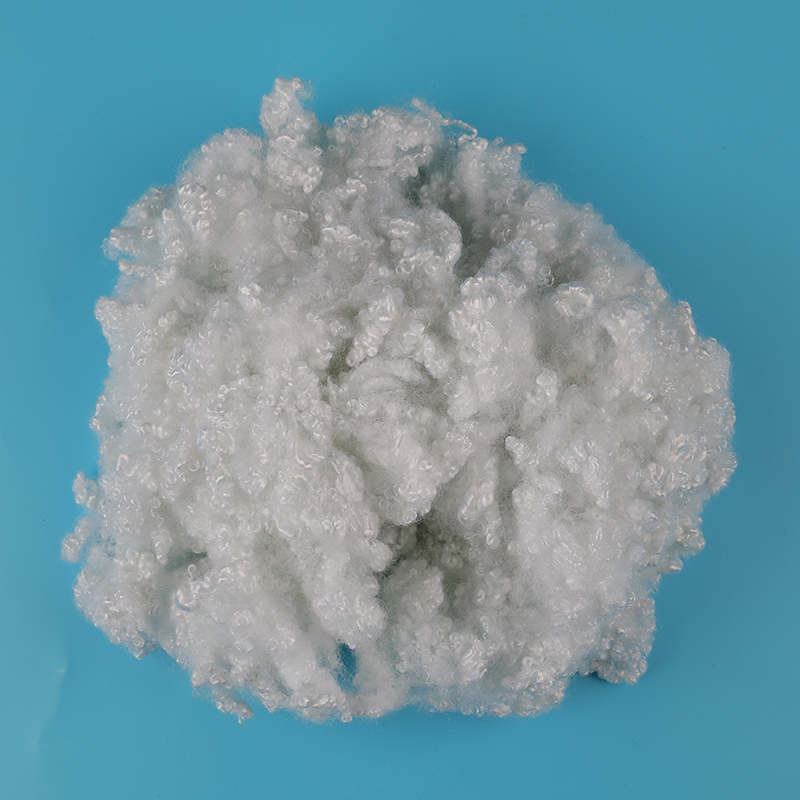

As China Custom Raw White Silicon Conjugated Polyester Staple Fiber 7D×64mm Manufacturers and Custom Raw White Silicon Conjugated Polyester Staple Fiber 7D×64mm Factory, We have built an advanced chemical plant with an annual recycling capacity of 50000 tons of Polyethylene Terephthalate (PET) flakes has been built in Huaibei, Anhui Province.

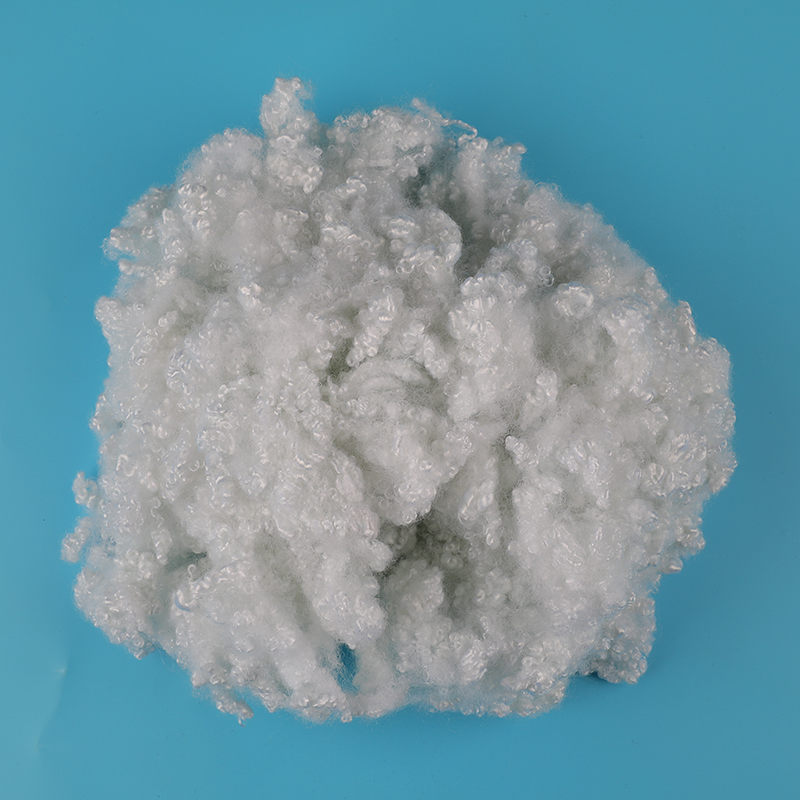

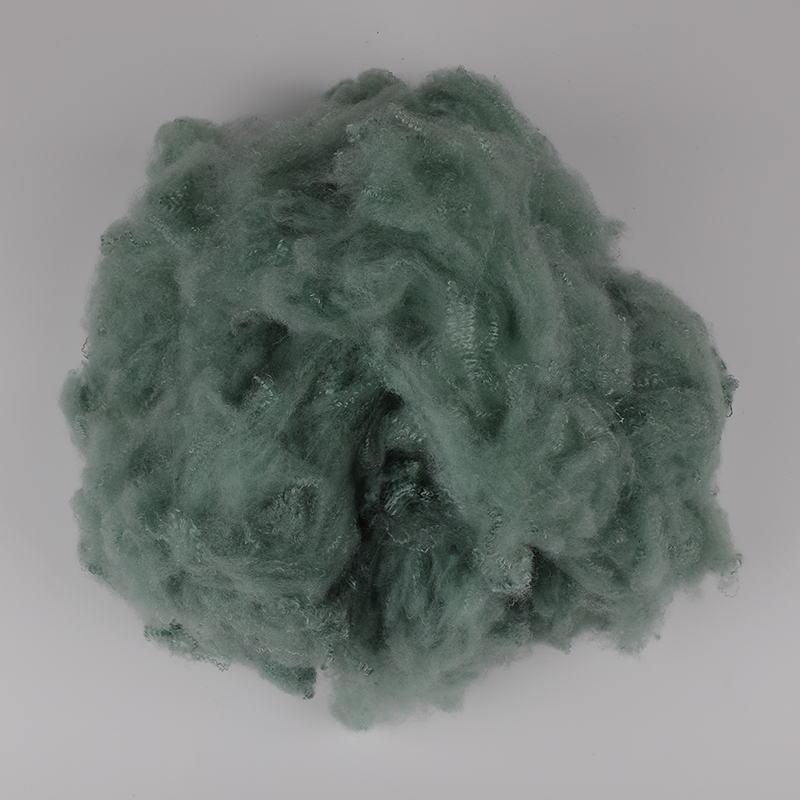

The main products are five series: composite ES fiber, non-woven fiber, hollow fiber, spinning fiber, electrostatic flocking tow.

Mission: to create a world class factory in the industry of differentiated chemical fibers and become industry leader in the field of differentiated chemical fibers.

English

English 中文简体

中文简体 Español

Español عربى

عربى